The housing shortage requires innovative solutions.

Prefab – the trademark construction method of Royal Homes in our 110,000-square foot production facility – is poised to be the perfect process for delivering high-quality custom homes in a pinch.

“There’s this push to build more efficiently, with infill projects,” our Kitchener client Jeremy said.

So Jeremy came to Royal Homes. His 80-year-old home facing Ottawa Street in Kitchener had a backyard surrounded by a hedge that would be perfect for an additional home.

If others couldn’t see the possibilities prefab provided at the time, he and Royal Homes could.

“No one thought we could put a house back there, but we did,” Jeremy said.

Since, Kitchener has moved to make “gentle density” a housing-crunch game plan, allowing up to four units to be built on what were previously considered single-home lots.

The new policy applies to more than 41,000 lots in the city.

According to a spring report, about 56,000 properties in Kitchener had only one dwelling. About 3,400 have two dwellings. About 500 had three. Three units per lot was approved in 2021.

The opportunities for an infill revolution are clear. Prefab can be a leading solution to making duplexes, triplexes and fourplexes commonplace throughout cities like Kitchener.

With Jeremy’s project, Royal was way ahead of local government’s revised strategy.

The prefab process is efficient and reliable, as Jeremy discovered. He figures what would have taken up to eight months in a traditional non-prefab build, only took a few weeks.

“It’s just a huge time-saver to have the modules made in the factory and have them arrive mostly finished,” Jeremy said. “It’s a new build so it’s all predictable. It all arrives. All the stuff is there. It’s just a matter of the finishing touches on site.”

There were two different construction approaches on Jeremy’s project.

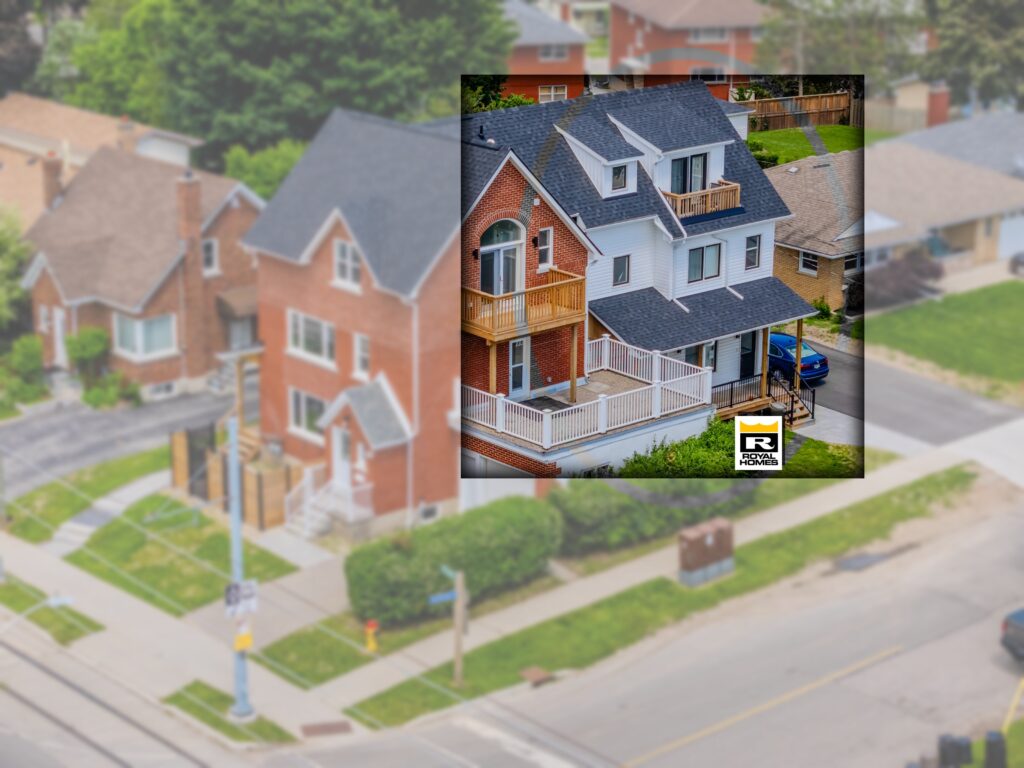

Royal Homes was called upon to install a whole new semi-detached house as an addition on the back. And Jeremy just finished rebuilding the existing red-brick house, adding a new third floor using traditional on-site construction.

The project started when Royal Homes delivered a brand new home, with a full separate new foundation, right beside the old red-brick home overlooking the Ion Light Rail Transit Line.

Four prefab modules for the new home facing the side street were constructed inside Royal’s production facility in Wingham.

Jeremy’s modules being built at our Wingham factory.

On delivery day, the four modules were driven to Kitchener and gently placed on the foundation by a big crane.

“The difference between the traditional build and the new build by Royal Homes was uncomparable” he said.

When rebuilding the old red brick house, it was time consuming and difficult, Jeremy says.

It took a full 12 months from cutting the roof off, demolishing parts of the interior, framing up the 3rd floor addition to add 600 square feet.

On the other hand, Royal Homes completed an addition of 3,000 square feet (including basement) in just 4 months. Having the majority of the home built in the factory helped fast-track the process while emphasizing quality.

Jeremy’s lot before a new foundation was dug for the second home.

Today, with his lot officially severed between the red-brick house and the Royal Home, Jeremy has two homes where one stood before.

His custom-built Royal Home has two residential units. The basement and the main floor is one unit. The top two floors make a second unit.

Both units have been rented since they were finished, he said.

Jeremy feels like he got the third floor for free, since the second floor modules arrived with the third floor deck pre-built, then the crew framed the loft roof on top.

Finishing work underway (top) after delivery day in 2020 (bottom).

“Cool and innovative,” Jeremy said of the design.

He found working with Royal Homes much less difficult than the traditional red-brick rebuild.

“Ten times easier,” he said.